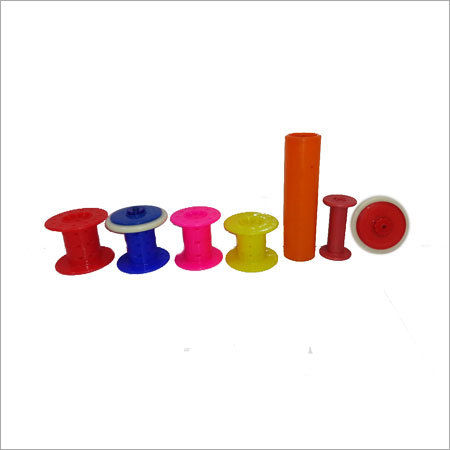

Textile Plastic Product

Price 10 INR/ Piece

Textile Plastic Product Specification

- Surface Finish

- Smooth

- Heat Resistance

- Yes

- UV Resistant

- Yes

- Leak Protection

- Yes

- Plastic Type

- Polypropylene

- Density

- 0.90 Gram per cubic centimeter(g/cm3)

- Melting Point

- Around 160C

- Tensile Strength

- 28 MPa

- Color Pattern

- Solid

- Type

- Textile Plastic Product

- Material

- Polymer (Plastic)

- Shaping Mode

- Injection Moulding

- Length

- Customized

- Weight

- Lightweight

- Hardness

- Medium

- Plastic Molding Type

- Injection Molding

- Color

- White

- Size

- Standard / Customized

- Tolerance

- ± 1 mm

- Packaging Type

- Carton Box

- Electrical Insulation

- Excellent

- Application

- Textile Machinery Components

- Impact Strength

- Good

- Flame Retardant

- No

- Corrosion Resistance

- High

- Usage

- Industrial Use

- Shape

- Custom / Standard

- Manufacturing Standard

- ISO 9001 Certified

- Abrasion Resistance

- High

- Recyclable

- Yes

Textile Plastic Product Trade Information

- Minimum Order Quantity

- 500 Pieces

- Supply Ability

- 80000 Pieces Per Month

- Delivery Time

- 7 Days

About Textile Plastic Product

Our company is one of the ruling entities in the field of manufacturing and supplying an exclusive range of Textile Plastic Product. We are offering a wide range of plastic products, which is widely used in various textile industries. These products are manufactured using quality plastic that is sourced from reliable suppliers of the market ensuring durability. Our Textile Plastic Product is stringently tested on various quality checking parameters ensuring flawlessness and defect-free nature.

Exceptional Durability and Performance

Crafted from top-grade polypropylene, these textile plastic components are noted for their remarkable abrasion and impact resistance. Their lightweight nature, combined with high tensile strength and excellent electrical insulation, ensures long-lasting performance in rigorous textile machinery environments.

Bespoke Design and Precision Manufacturing

Our products are available in standard and custom designs, with tolerances maintained at 1 mm. Injection molding technology ensures accurate dimensions, smooth surface finish, and consistency, catering to various industrial requirements and unique machinery specifications.

Safe, Eco-Friendly, and Reliable

Every component not only delivers superior leak protection and high corrosion resistance but is also made from recyclable materials. With no flame retardants, it values operator safety and environmental consciousness while complying with ISO 9001 quality benchmarks.

FAQs of Textile Plastic Product:

Q: How are these textile plastic products used in textile machinery?

A: These plastic components act as vital parts within textile machines, offering support and protection against abrasion and chemical exposure, ultimately enhancing machine longevity and operational safety.Q: What benefits does your polypropylene plastic offer for industrial textile applications?

A: Polypropylene provides high corrosion and abrasion resistance, durability, and electrical insulation, making it ideal for the harsh environments found in textile manufacturing settings. Its lightweight nature also eases installation and operation.Q: When should custom sizing be considered for textile plastic products?

A: Custom sizing should be selected when machinery requires non-standard dimensions or specific tolerances, ensuring optimal fit and function for unique or specialized equipment.Q: Where are your textile plastic products manufactured and supplied from?

A: All products are manufactured and supplied from our ISO 9001 certified facility in India, ensuring strict adherence to international quality standards throughout the production process.Q: What is the process behind the production of these components?

A: Each component is precisely crafted using injection molding technology, which enables high accuracy in detail, smooth finishes, and consistent quality for both standard and customized shapes.Q: How does the products heat and UV resistance benefit textile operations?

A: Withstanding temperatures up to 120C and protecting against UV degradation, these components are well-suited for extended use in demanding, high-temperature textile production environments.Q: Is your textile plastic product environmentally friendly?

A: Yes, the product is fully recyclable and designed without flame retardants, supporting eco-friendly practices while still delivering robust industrial performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Texturising Tube Category

Texturising Tube

Price Range 35.00 - 70.00 INR / Piece

Minimum Order Quantity : 500 Pieces

Color Pattern : Plain

Shaping Mode : Extrusion

Tensile Strength : 30 MPa

Type : Texturising Tube

Plastic Texturising Tube

Minimum Order Quantity : 500 Pieces

Color Pattern : Plain

Shaping Mode : Molded

Tensile Strength : 32 MPa

Type : Plastic Texturising Tube

Plastic Paper Tube

Price Range 35.00 - 70.00 INR / Piece

Minimum Order Quantity : 500 Pieces

Color Pattern : Solid/Plain

Shaping Mode : Round Molded

Tensile Strength : Good

Type : Plastic Paper Tube

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS