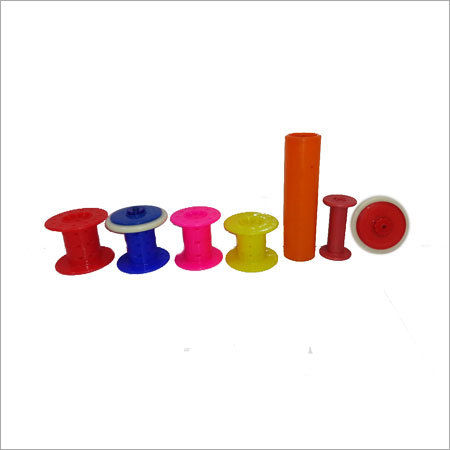

Plastic Texturising Tube

Price 10 INR/ Piece

Plastic Texturising Tube Specification

- Surface Finish

- Smooth, Textured Options

- Color Pattern

- Plain

- Melting Point

- 160C

- Leak Protection

- Leak Proof

- Heat Resistance

- Yes

- Plastic Type

- Polypropylene (PP)

- Tensile Strength

- 32 MPa

- UV Resistant

- Yes

- Type

- Plastic Texturising Tube

- Material

- High Quality Plastic

- Shaping Mode

- Molded

- Length

- Customizable, Standard 600 mm

- Hardness

- Rigid

- Plastic Molding Type

- Injection Molding

- Color

- White, Blue, Custom Colors available

- Size

- Standard and Custom Sizes

- Chemical Resistance

- Resistant to acids, alkalis, and solvents

- Compliance

- RoHS compliant

- Reusability

- Reusable and recyclable

- Packing Type

- Carton or Polybag packing

- Application

- Used in textile yarn processing and winding

Plastic Texturising Tube Trade Information

- Minimum Order Quantity

- 500 Pieces

- Supply Ability

- 80000 Pieces Per Month

- Delivery Time

- 7 Days

About Plastic Texturising Tube

Our company is a renowned entity famous for manufacturing and supplying excellent quality Texturising Tube. Our manufactured tubes are widely used in textile manufacturing units due to their easy to fit nature and durability. These tubes are designed and developed under the guidance of our skilled professionals, as per the industrial laid norms. Our manufactured Texturisng Tube is checked on various quality checking parameters ensuring flawlessness and defect-free nature. Moreover, we provide door-step delivery of these tubes at our patrons end.

Versatile Application for Textile Processing

Plastic Texturising Tubes are specially constructed for the yarn processing and winding phase in textile manufacturing. Their chemical resistance makes them ideal for use in demanding environments, ensuring the longevity and integrity of both the tube and the yarn. With customizable dimensions, these tubes seamlessly integrate into various textile machinery setups, enhancing operational efficiency.

Engineered for Durability and Sustainability

Manufactured using high-quality polypropylene and injection molding technology, these tubes are designed to be both tough and eco-friendly. Their rigid structure offers excellent support for processing activities, while their ability to resist heat, UV exposure, and chemicals guarantees a long product lifespan. Being reusable and recyclable, they align with sustainable production goals in industrial settings.

FAQs of Plastic Texturising Tube:

Q: How are Plastic Texturising Tubes typically used in industrial settings?

A: These tubes are primarily employed during the yarn processing and winding stages in textile manufacturing. Their strength and chemical resistance make them ideal for holding, supporting, and transporting yarn through various production phases, ensuring efficient and uncontaminated processing.Q: What benefits result from using polypropylene for these tubes?

A: Polypropylene provides excellent chemical, heat, and UV resistance, resulting in tubes that withstand harsh industrial conditions. Its lightweight yet rigid nature ensures the tubes maintain shape under stress, and its recyclability supports environmentally responsible practices.Q: When is it recommended to choose a textured surface finish?

A: A textured surface finish is beneficial when additional grip or friction is required to secure the yarn during high-speed processing. It helps prevent slippage, maintains even winding, and can improve operational output, depending on specific machinery requirements.Q: Where can the length and color of the tubes be customized?

A: Customization options are available directly from the manufacturer or supplier in India. You can specify preferred colors and tube lengthsincluding the standard 600 mm or other tailored dimensionsto suit your equipment or branding needs.Q: What packing options are offered for these tubes?

A: Plastic Texturising Tubes are available in both carton and polybag packing, allowing customers to choose the packaging type that best meets their handling, transport, and storage demands.Q: How does RoHS compliance enhance the products suitability?

A: RoHS compliance signifies that these tubes are free from hazardous substances, making them safe for use in industries that demand adherence to environmental safety standards, while also protecting users and finished products.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Texturising Tube Category

Texturising Tube

Price Range 35.00 - 70.00 INR / Piece

Minimum Order Quantity : 500 Pieces

UV Resistant : Yes

Shaping Mode : Extrusion

Type : Texturising Tube

Surface Finish : Smooth

Textile Plastic Product

Minimum Order Quantity : 500 Pieces

UV Resistant : Yes

Shaping Mode : Injection Moulding

Type : Textile Plastic Product

Surface Finish : Smooth

Plastic Paper Tube

Price Range 35.00 - 70.00 INR / Piece

Minimum Order Quantity : 500 Pieces

UV Resistant : No

Shaping Mode : Round Molded

Type : Plastic Paper Tube

Surface Finish : Smooth

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS